Technical Areas

What problems are we tackling?

1.

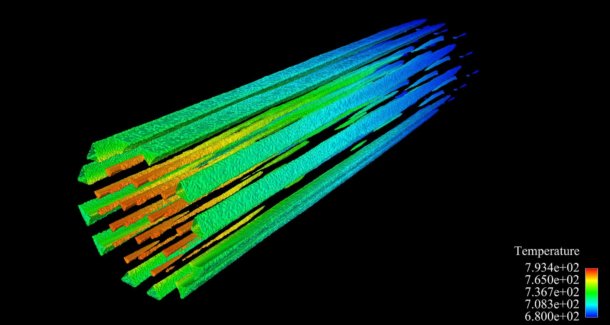

Development of efficient multiphysics models of nuclear reactors to accurately capture the feedback mechanisms between fuel performance, neutronics, and system thermal-hydraulics during steady-state operation and transients.

2.

Predictive multiscale fuel performance and structural materials modeling that accurately simulates thermomechanical response in extreme radiation, temperature, and chemistry environments and leverages targeted experiments to quantify uncertainties supportive of industry and NRC decision-making.

3.

Establish predictive capability for thermochemistry and physical properties of fluid salts, with complex chemistry induced by fission product generation, and their corrosive interaction with structural materials under high temperature and irradiation, leading to probabilistic margin and failure predictions.

4.

Multiscale thermal hydraulics capability, including a particular focus on the prediction of two-phase heat transfer and flow, from high resolution computational fluid dynamics (CFD) to full-system simulation.

5.

Integrating experimental and in-line operational data, and modeling and simulation through advanced data science approaches that maximizes the value of experiments, optimizes the use of U.S. Department of Energy (DOE) research facilities, provides confidence in predictive capabilities, and improves understanding of current and future nuclear energy systems.

Fuel Performance

The objective of the Fuels Technical Area is to deliver an integrated set of predictive computational tools for nuclear fuel performance analysis and characterization in order to enable timely qualification of new fuels and performance optimization. The multi-scale approach to nuclear fuel performance adopted by the Fuels Technical Area intelligently combines modeling and simulations with targeted separate effects testing, limited integral testing, and uncertainty quantification. It offers an attractive alternative to the historical qualification approach heavily reliant on expensive and time-consuming integral testing.

Reactor Physics

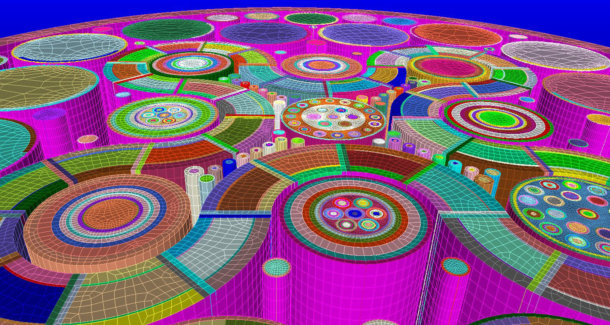

Reactor physics modeling and simulation quantifies particle-nuclide interactions, nuclide decay transitions, and their respective energy-release and secondary particle release. These reaction rates underpin the calculation of design and safety quantities of interest and detailed design quantities of interest.

Since the inception of the Nuclear Energy Advanced Modeling and Simulation (NEAMS) and Hub programs, the U.S. Department of Energy has invested in HPC-based transport solutions with higher energy and spatial fidelity than legacy approaches, with inline cross section generation and depletion/decay. Higher fidelity solutions provide means for tuning or assessing two-step legacy approaches and exploration into phenomena for which legacy approaches are limited or intractable.

Tools

BISON is the Nuclear Energy Advanced Modeling and Simulation’s (NEAMS) program primary fuel performance code. It embeds emerging technology for advanced fuel performance computation in multiple options for dimensions, physics, coupling approaches, and length scale information, depending on application and industry requirements. Industry can use these tools independently, supplement use of existing tools, or consult with NEAMS modeling experts to implement a multi-faceted approach to fuels performance calculations.

A practical hierarchical approach is taken for exchanging information between scales, as opposed to concurrent coupling. This multiscale approach is based on the conviction that deriving fuel behavior from an instantaneous knowledge of fuel chemistry and microstructure, rather than by correlating it to an empirical metric such as “burnup,” delivers an unprecedented degree of predictability in nuclear fuel performance.

Tools and Benchmarks

The Reactor Physics Technical Area delivers reactor physics computational tools that support a broad range of spatial and energy fidelity, spanning user needs for preconceptual design analysis, licensing analysis, detailed design and operational analysis, and reference solutions.

The Reactor Physics Technical Area also supports the maintenance and development of the International Reactor Physics Experiment Evaluation IRPhE Handbook and the International Criticality Safety Benchmark Evaluation Project (ICSBEP) Handbook, qualified benchmark datasets collected from validation experiments worldwide. These handbooks provide validation data for the developed tools and requisite nuclear data sources.

Structural Materials and Chemistry

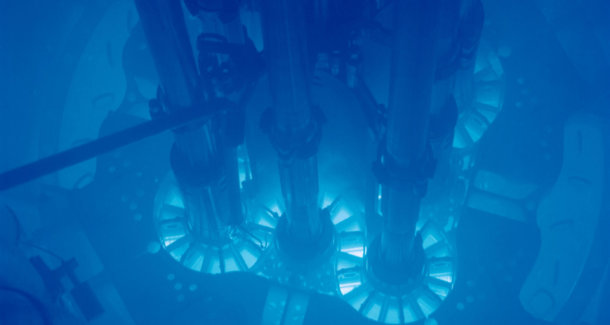

Current operating light-water reactors and proposed non-light water reactors contain structural components subjected to aggressive environments that must safely perform their intended functions after being subjected to environmental degradation. Decisions regarding the safe long-term operation of existing reactors and aging management strategies for proposed reactors require understanding the progression of degradation mechanisms and the ability of reactor structures, systems, and components to safely perform under the progression of degradation.

Thermal Fluids

The Thermal Fluids Technical Area advances the state of the art of thermal-hydraulic simulations by researching novel solution strategies for historically challenging flow issues that light-water and non-light-water reactors.

The Thermal Fluids Technical Area includes the Center of Excellence for Thermal-Fluids Applications in Nuclear Industry, a group formed by laboratory and university counterparts that aims for close collaboration with reactor vendors with consultation from the U.S. Nuclear Regulatory Commission. The mission of the center is to provide a front-end to the advanced reactor industry for thermal-fluids problems, demonstrate the use of T/H tools for industrial use, and stimulate collaborations.

Tools

A set of engineering-scale tools based on a common multiphysics simulation platform are being developed, permitting coupling between chemistry and structural material degradation codes. Safety assessments of structural components and heat transfer fluid chemistry involve engineering-scale computations. When experimental data is available to support empirical models of degradation in the applicable regimes, those models are used in engineering-scale computations. However, in many cases experimental data is not available for regimes of interest due to the difficulty in obtaining data over the time scales or under the environmental conditions of interest. In these cases, multiscale simulation tools are being developed to address both of these issues. The multiphysics, multiscale capabilities are a unique, defining characteristic of these tools.

Tools

Our advanced T/H research and development approach synergistically combines three length and time scales in a hierarchal multi-scale approach:

- Lower Length Scale: The Lower Length Scale focuses on resolving the high-resolution physics associated with single and multi-phase, highly turbulent conjugate heat transfer (CHT) with highly resolved thermal boundary layers (heat flux).

- Engineering Length Scale: The Engineering Length Scale integrates coarse mesh approaches for homogenized multi-dimensional CHT, such as those found in gas-cooled pebble-bed reactors.

- System Scale: System Scale analysis for nuclear reactors is composed of one-dimensional fluid flow pipe networks and zero-dimensional system components. These classes of algorithms and corresponding approaches are reduced order models (ROM) of the more complex scales and allow for more efficient calculations. These reduced order systems rely heavily on empirical correlations or models, as many of the flow features and phenomena are no longer resolved.

Multiphysics Applications

Nuclear reactors rely on the interaction of multiple physics phenomena in order to operate. In accident conditions, most reactor concepts are designed with inherent safety in mind; multiphysics provide feedback effects to effectively shut down the reactor. Individual physics codes can capture a description of the reactor given appropriate boundary conditions, but multiphysics simulations are needed in order to predict behavior in both steady state and transient phenomena.

Nuclear reactors rely on the interaction of multiple physics phenomena in order to operate. In accident conditions, most reactor concepts are designed with inherent safety in mind; multiphysics provide feedback effects to effectively shut down the reactor. Individual physics codes can capture a description of the reactor given appropriate boundary conditions, but multiphysics simulations are needed in order to predict behavior in both steady state and transient phenomena.

The Multiphysics Applications Technical Area enables the development of multiphysics simulation capabilities that address specific needs of the nuclear reactor community. The Multiphysics Applications Technical Area identifies stakeholder-driven multiphysics requirements for different reactor concepts and enables development of efficient and quality multiphysics tools by coupling individual physics codes. This Technical Area is charged with development of the MOOSE Framework which is the underlying foundation of numerous NEAMS tools and also enables coupling between non-LWR applications. Additionally, this Technical Area develops the VERA LWR multiphysics code suite. Finally, this Technical Area supports end user workflow and input/output processing through the NEAMS Workbench.

Multiphysics simulations are demonstrated and assessed through in both light-water (LWR) and non-light-water (non-LWR) areas. The LWR Applications activities focus on engagement with the LWR industry, proposing new modeling and simulation functionalities to address relevant LWR challenge problems, and applying/assessing these functionalities through the use of the program’s LWR tools. The non-LWR Applications activities focus on proposing and testing the functionalities of Fast Reactors, High Temperature Gas Reactors, Micro-Reactors, Molten Salt Reactors, and Advanced Reactor Source Term. Given the diversity of reactor designs from industry, there may be some overlap in terms of categorization; some reactor designs may benefit from the work from multiple categories.

Tools

The MOOSE framework is used for physics code coupling within the Nuclear Energy Advanced Modeling and Simulation (NEAMS) program, due to its strong focus on software quality assurance and its built-in ability to provide flexible solution transfers.

NEAMS Workbench is the main user interface for both single physics and multiphysics tools. NEAMS Workbench is used to facilitate input and output processing, and to assist with workflow management. Once familiar with Workbench, the user can increase their access to additional physics tools and workflows with minimum effort.

VERA is used to solve neutronics, thermal-hydraulics, fuel performance, and coupled physics problems for LWRs. It integrates physics components based on science-based models and state-of-the-art numerical methods.

Activities

Requirements Development

The Multiphysics Applications Technical Area helps ensure that the products developed from the Nuclear Energy Advanced Modeling and Simulation (NEAMS) program are relevant and useful. It provides input to the other five technical areas on functional requirements for different reactor technologies, to help prioritize code development capabilities. This input is informed by stakeholder engagement activities with industry, the U.S. Nuclear Regulatory Commission, other U.S. Department of Energy programs, and discussions with members of the NEAMS Extended and Senior Leadership Teams.

Testing

The Multiphysics Applications Technical Area serves as an internal user testing ground for newly developed code functionalities by applying them to challenge problems that are relevant to stakeholders. This is an essential step in the code development process for testing functionality, providing feedback to developers, improving usability, and reducing the learning curve so that these burdens are not passed on to the customers.

Verification and Validation

Where applicable, the Multiphysics Applications Technical Area also performs verification and validation of NEAMS end products and, once the functionalities have been determined to be implemented successfully, demonstrations of NEAMS capabilities to external stakeholders.

Virtual Test Bed

The Virtual Test Bed is a National Reactor Innovation Center initiative that facilitates the use of NEAMS advanced modeling and simulation tools. The Virtual Test Bed hosts a wide variety of example challenge problems based on advanced reactor designs and provides an open-source virtual space for building and testing various components, systems, and complete pilot plants.